Climatic testing puts a product through a range of scenarios – from heat to cold, humidity to pressure – to ascertain how well it can withstand different environments.

The testing procedure is useful for exposing technical products and devices to the kind of real-world stresses and strains a device will undergo on the market.

Temperature, humidity and other climatic influences can affect the performance of electronic products, parts and components, or even cause their failure. Climatic testing can simulate the life cycle environments that are encountered by a product and ensures the product can perform satisfactorily in its intended environments.

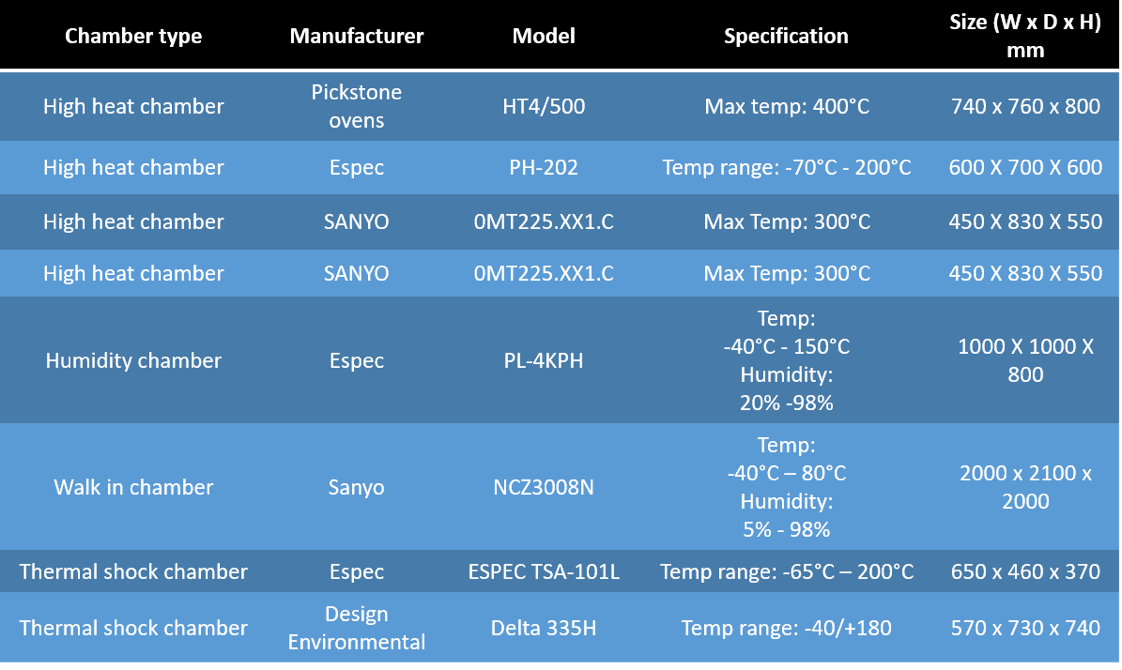

Panasonics product compliance group have extensive experience in climatic testing and uses high performance test equipment all located in one site. A summary of the chambers can be seen in the table on the right.