Glow Wire Testing

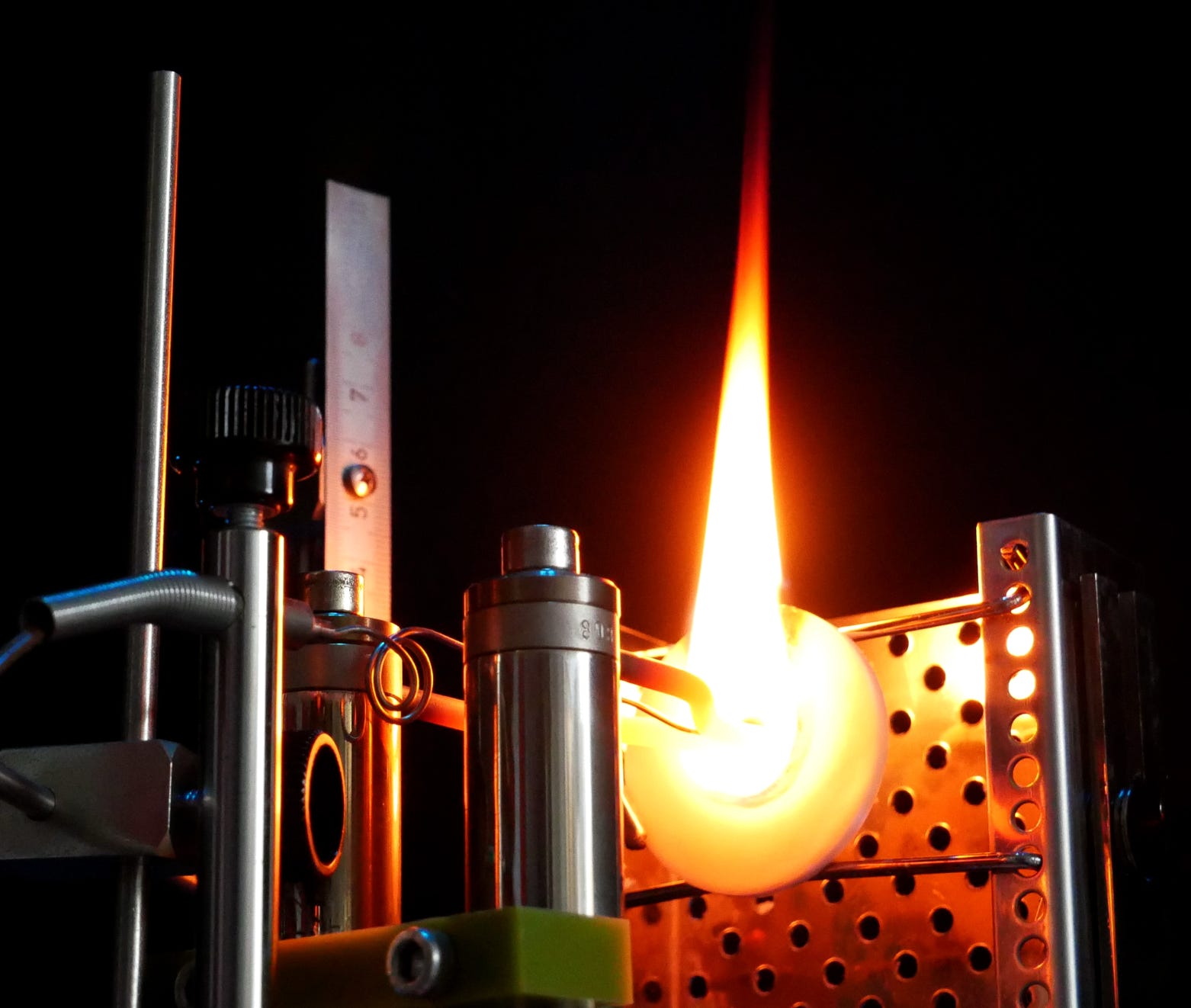

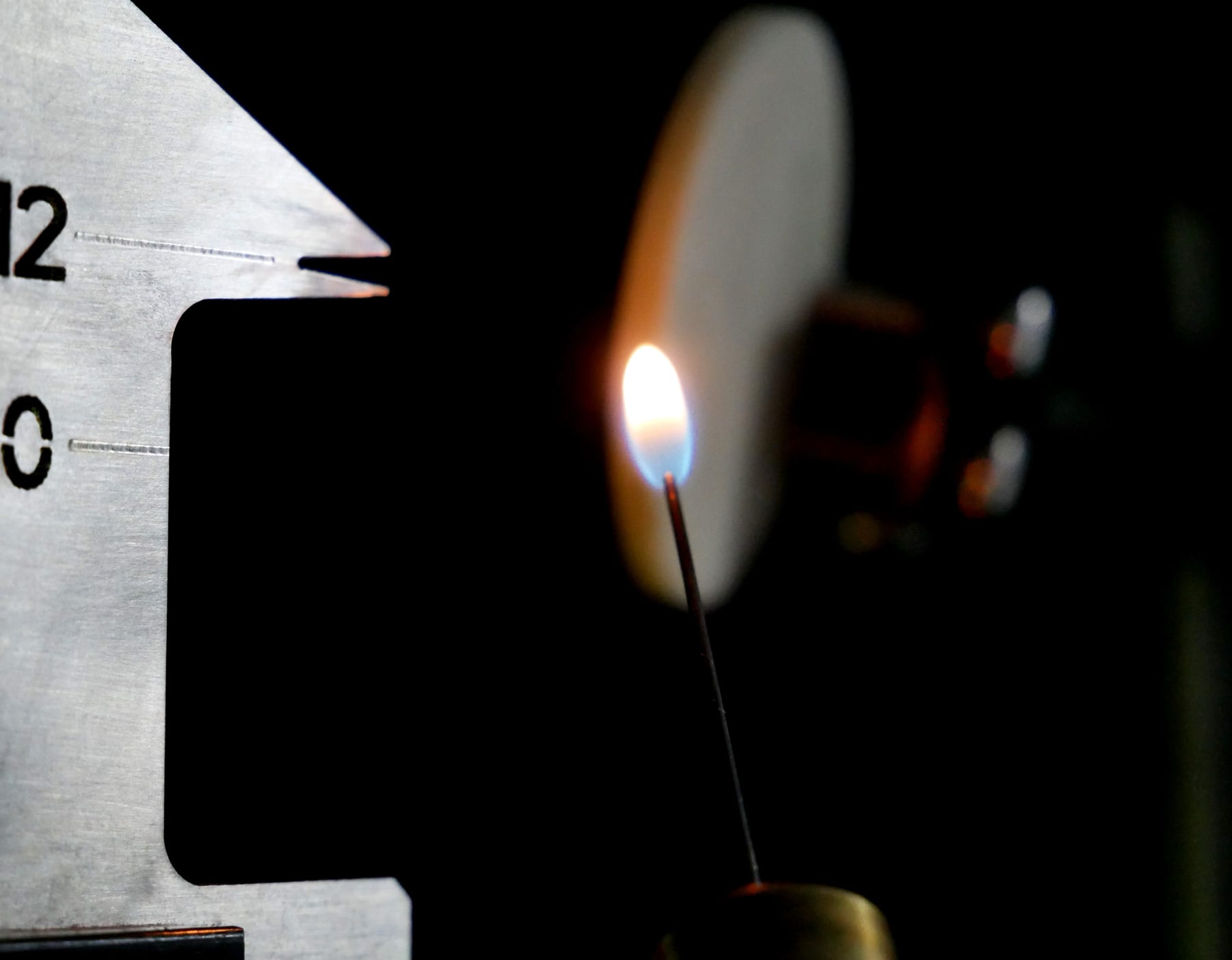

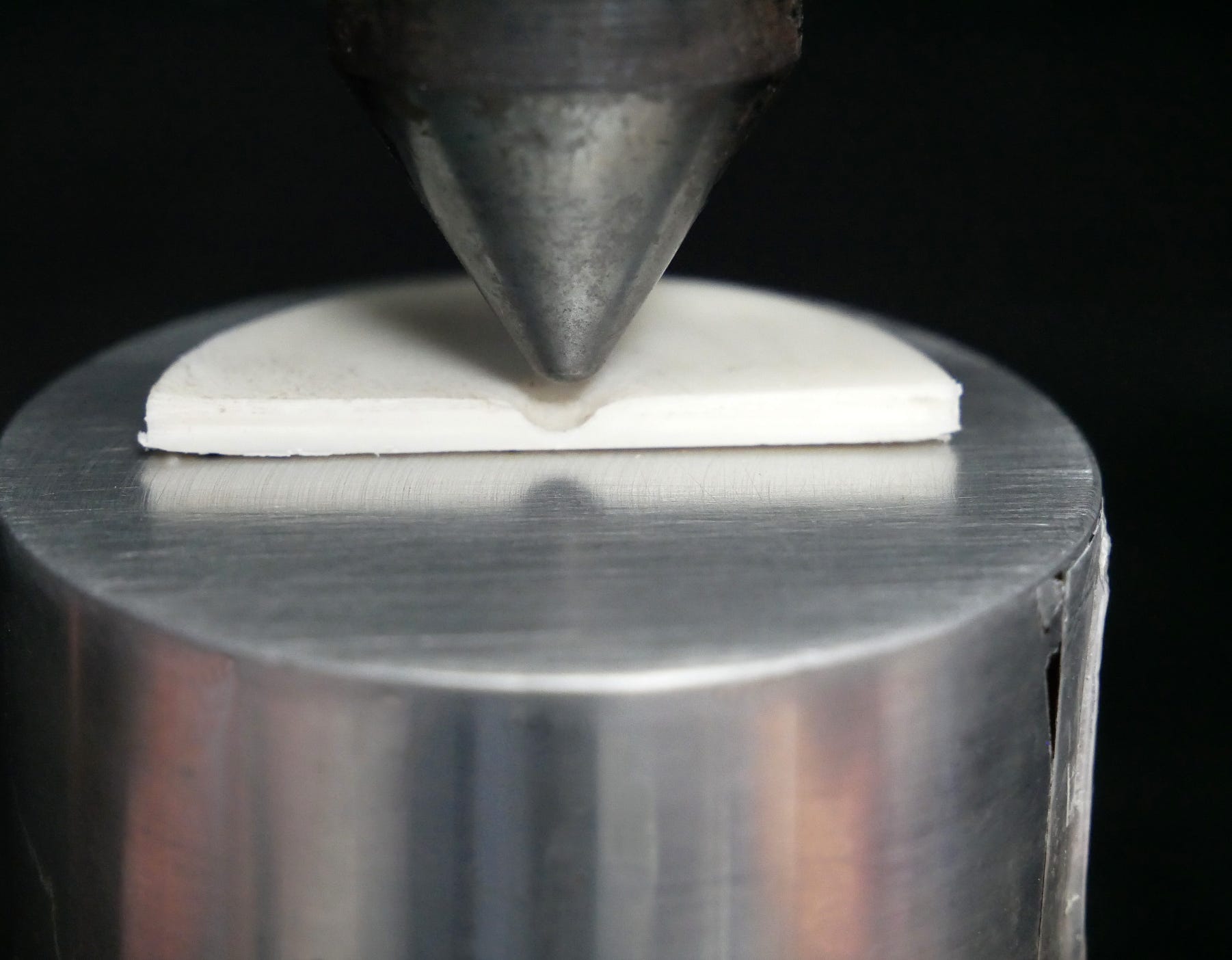

The glow wire test subjects plastic material, components or like thermal stresses that may occur during fault conditions to assess their flammability ratings.

At Panasonic, the glow wire test is performed and assessed against the following standards:-

- EN/IEC 60695-2-10 : Glow wire test equipment and general test method

- EN/IEC 60695-2-11 : Tests with the glow wire for flammability of end products (GWEPT)

- EN/IEC 60695-2-12 : Testing with glow wire for flammability of materials (GWFI)

- EN/IEC 60695-2-13 : Tests with the glow wire for the flammability of materials (GWIT)